We develop individual solutions for you

– across all industries and perfectly adjusted due to your requirements.

Competences

Project examples

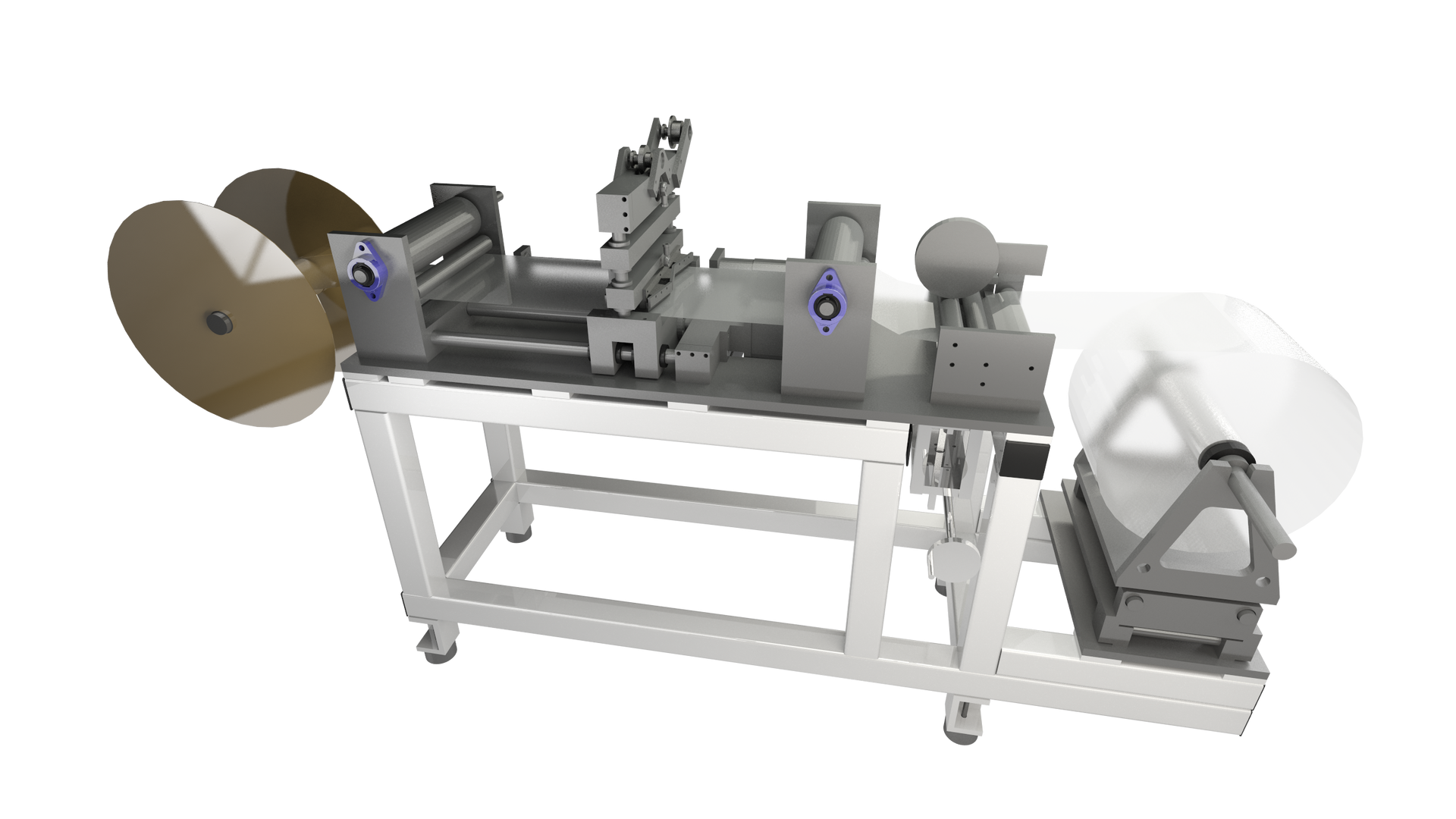

Cutter

Cutter for sheet metal coils

In order to cut pieces from metal sheet coils, a machine is needed through which the product passes. A measuring instrument determines at which instance the coil is cut. This machine respects small dimensional tolerances within a high production speed. Additionally, the machine features an integrated sheet leveller. The cutting is done by a cross cutter.

This example shows you that we build fast and precise machines. What can we do for you? Your contact person is Mr. Andreas Heidler, phone: +49 911 / 94 05 331.

Container platform

Containerplattform

Container platform for transporting and handling heavy objects.

- Max. loading area selectable:

- up to L = 6,000 mm, up to W = 2,500 mm

- Max. load:

- depending on the version up to 10 t

- Rail-bound

- security system

- Travel speed:

- up to 10 meters / minute

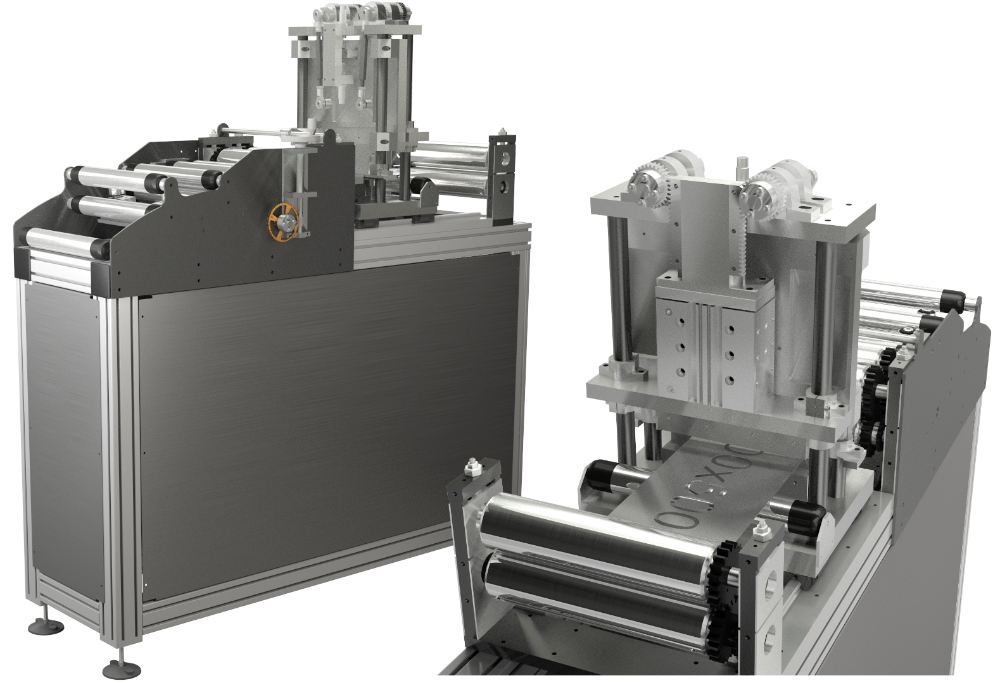

Foil cutter

Foil cutter für precise cutting

Foil materials are difficult to handle. The cutting, perforation and longitudinal cut of foils require machines that work precisely as well as at a high speed.

The foil cutting machine developed at Heidler Special Machines displays all of these features. In addition to a high production speed, it guarantees very narrow dimensional tolerances.

This example shows you , that we build fast and precise machines. What can we do for you? Don't hesitate to contact us! Your contact person is Mr. Andreas Heidler. Phone: +49 911 / 94 05 331.

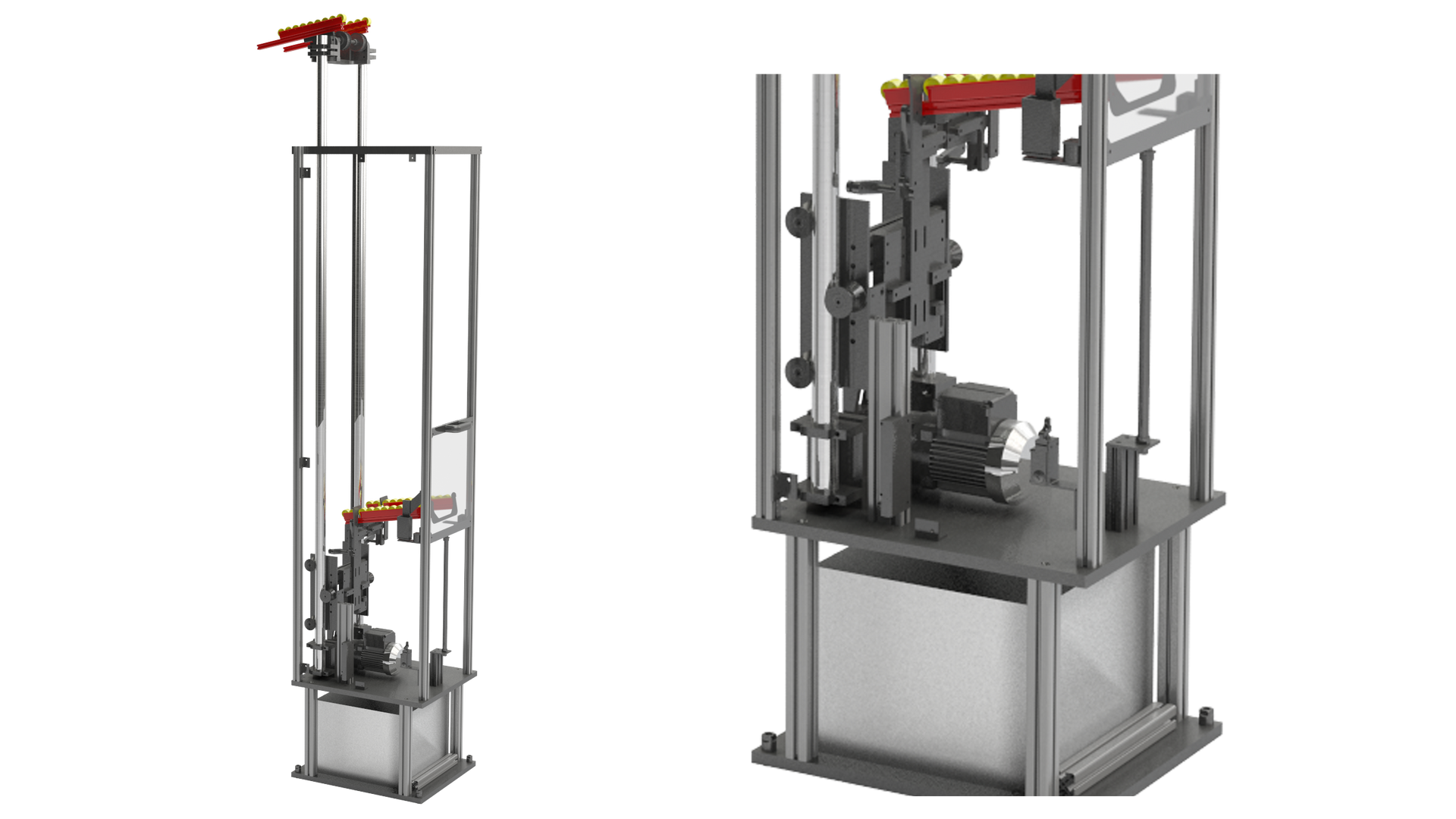

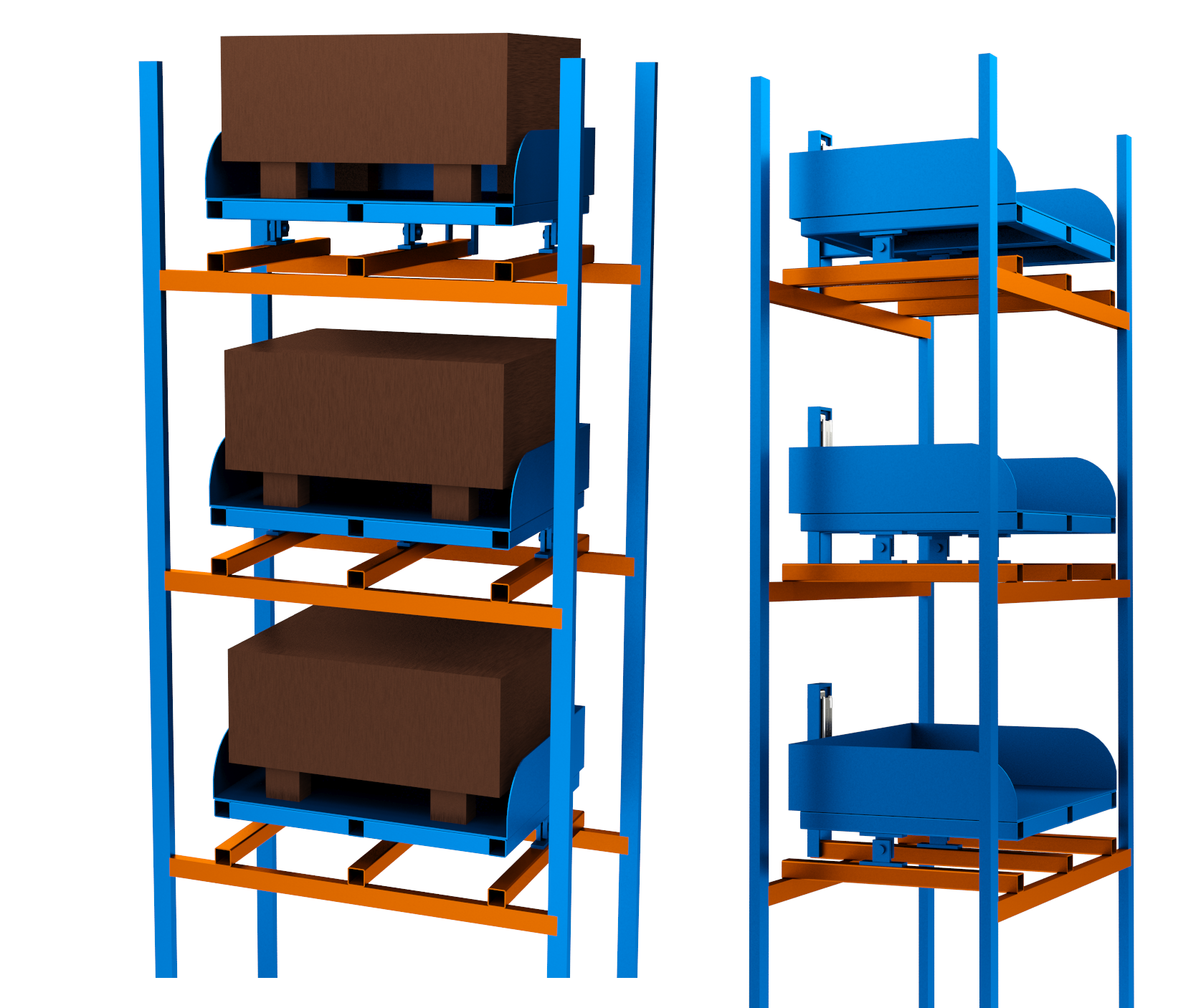

Lifting device

Lifting device for the transportation of goods

This version of a small-sized lift pulls out the transported good automatically in the unloading position. Depending on the spatial conditions, this machine can move upwards vertically as well as diagonally. It can be used with a transport bracket for the transported good as well as without one. The lifting height is adaptable to suit individual requirements.

This example shows you that we build fast and precise machines. What can we do for you? Don't hesitate to contact us! Your contact person is Mr. Andreas Heidler, phone: +49 911 / 94 05 331.

Food industry

Machine for food industry

Machines used for the processing of fresh, cooled or frozen food need to satisfy very strict requirements. For the food industry and the agricultural sector it is of utmost priority to meet the hygiene and cleanliness requirements when processing food, for example during picking, washing, separating, transporting, and packaging. That is why it is important to Heidler Special Machines that the design of our machines allow for easy cleaning. The material we primarily use in fabrication is stainless steel or suitable plastics, where appropriate.

This example shows you that we build fast and precise machines. What can we do for you? Don't hesitate to contact us! Your contact person is Mr. Andreas Heidler, phone: +49 911 / 94 05 331.

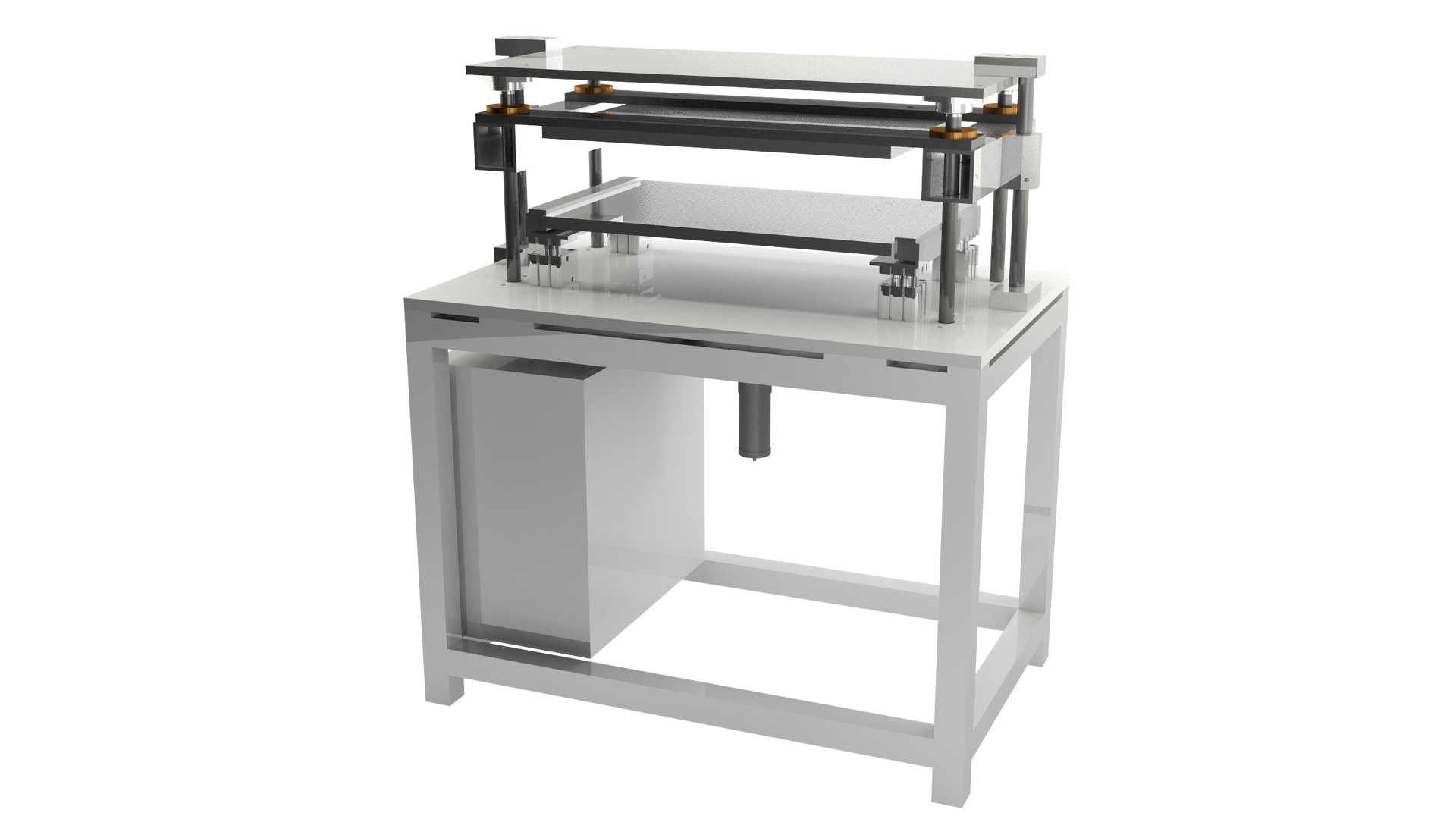

Pressing technique

Powerful pressing machine

The pressing of industrial materials requires robust machines with sufficient stability and stiffness as well as necessary power. At the same time these machines must move precisely. The machine presented here allows for a precise and fine adjustment of the pressing force.

This example shows you that we build fast and precise machines. What can we do for you? Don’t hesitate to contact us! Your contact person is Mr. Andreas Heidler, phone: +49 911 / 94 05 331.

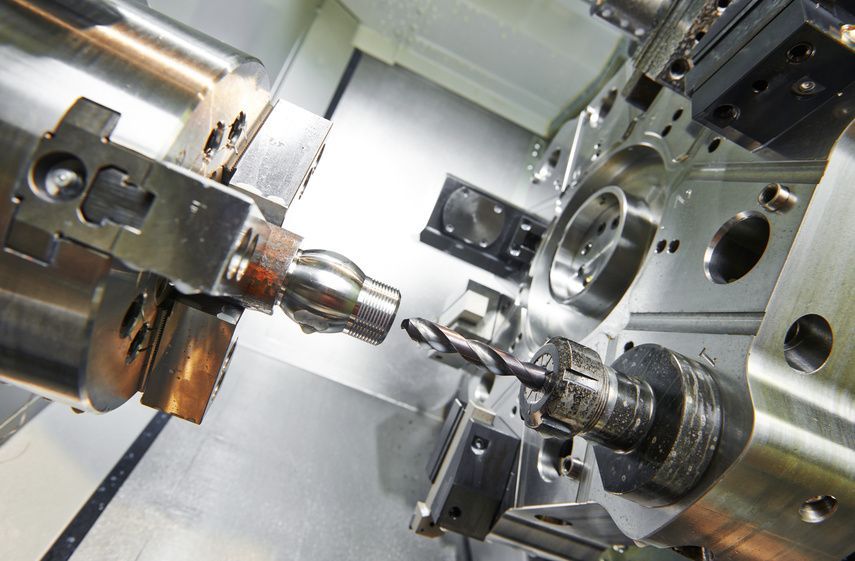

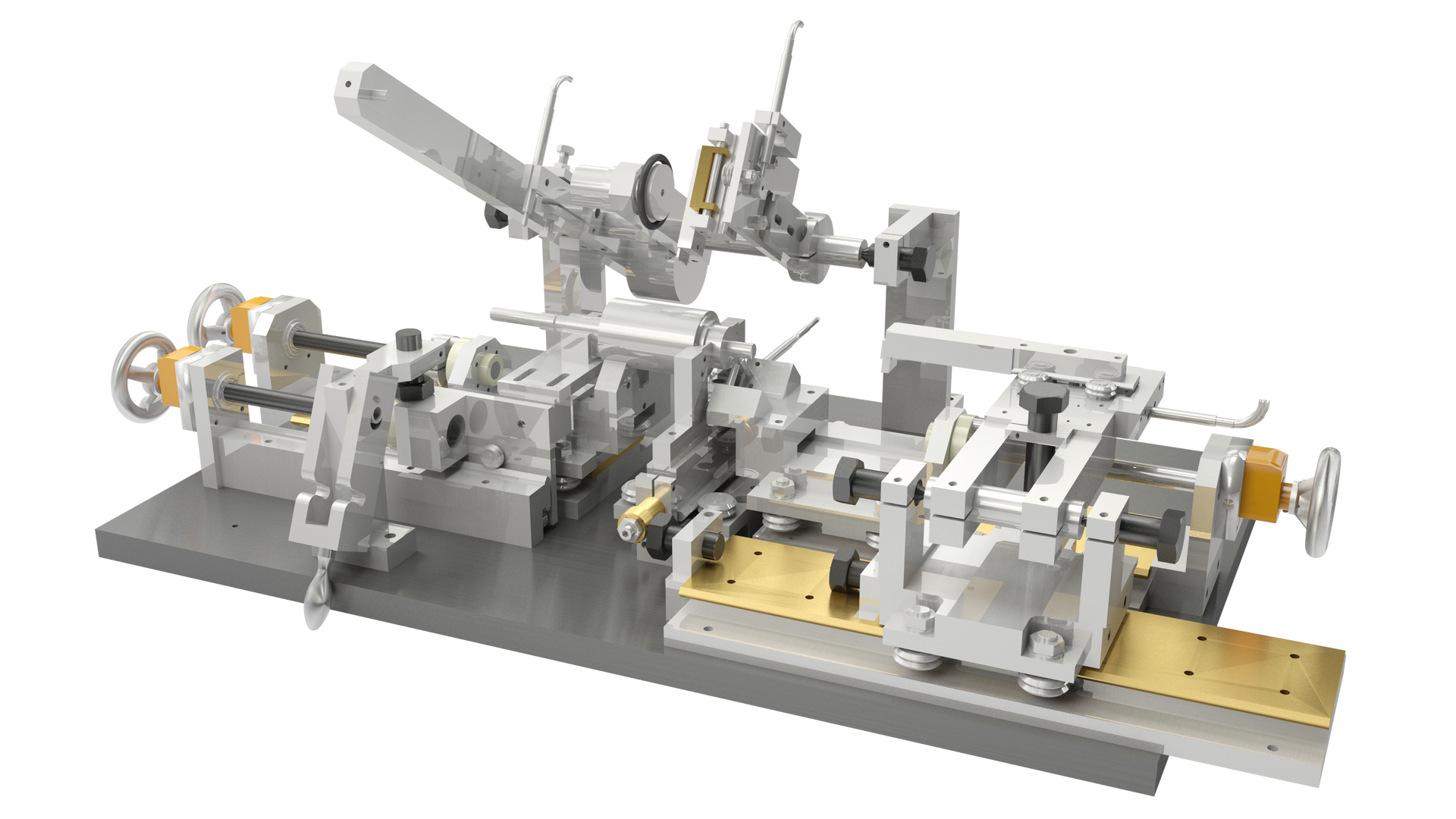

Testing instruments

High precision testing device

For a continuous production and quality control, Heidler Special Machines built a measuring machine for a company working within the automotive industry. The precision mechanics for measuring had to work at the highest precision – a requirement which can be fulfilled only if minimum unit tolerances are observed.

This example shows you that we build fast and precise machines. What can we do for you? Don't hesitate to contact us! Your contact person is Mr. Andreas Heidler, phone: +49 911 / 94 05 331.

Dry device

Robust dry device

This three meter high chip dryer offers a vast range of applications. For example, it may be used to recycle cooling lubricants. The chip containers are also available in extra large sizes. They are built to be robust and contain an oil and dirt separator. The height of the machine can be made to order.

This example shows you that we build robust and ressource-saving machines. What can we do for you? Don't hesitate to contact us! Your contact person is Mr. Andreas Heidler, phone: +49 911 / 94 05 331.

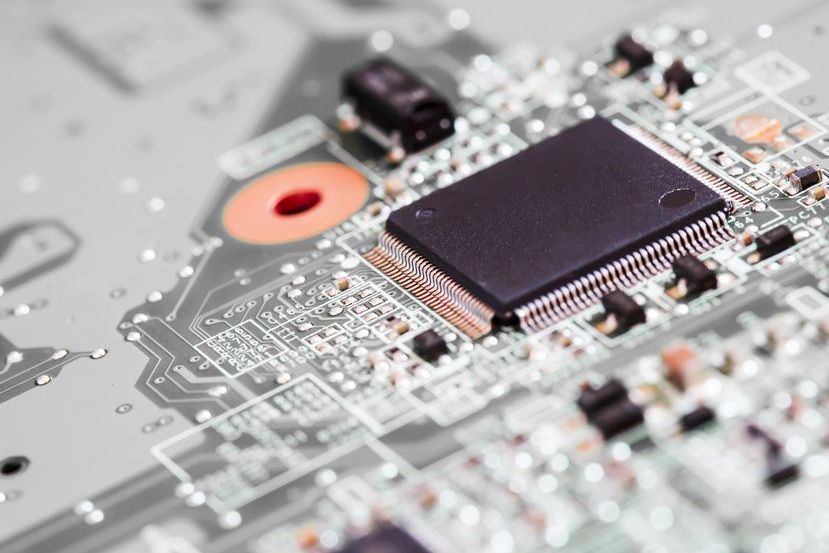

About Us

Reliable and flexible, fair and service-oriented:

that's how we are described by our clients, for whom we develop and construct special machines. Heidler Special Machines was founded in 2004 by graduate engineer (FH) Andreas Heidler. Since then, our engineers, master craftsmen and skilled workers have built approximately one hundred machines for individual needs.

The starting point of our work is always the needs of our customers.

So we attach great importance to solid consultation. From there we develop concrete concepts, show you various options and recommend to you the best solutions – always bearing in mind the economic efficiency. Our construction and production is as sustainable and as environmentally sound as possible.

Consultation, development & construction, mechanical engineering

as well as steering & electrical engineering are our basic competences. Our broad portfolio makes it possible: Whatever you need, we do it for you. Even if you need solutions that don't exist yet.

Don't hesitate to contact us! Your contact person is Mr. Andreas Heidler. For direct contact, phone: +49 911 / 94 05 331.

Contact

Heidler Sondermaschinen

Almoshofer Hauptstraße 46-48

90427 Nuremberg - Germany

Mail: info(at)heidler-sondermaschinen.de